(1) the rubber connector should be located on the side of the water pump when it is used at the inlet and outlet of the water pump. The metal diameter reducing connector should be installed between the rubber connector and the water pump, and it should be installed at the large diameter of the diameter changing.

(2) during construction, it must be in a natural state, and do not cause artificial deformation of the product during installation; Rubber joints are strictly forbidden to exceed the displacement limit during installation.

(3) when rubber joints are installed in flat, suspended and vertical positions, the actual axial displacement pressure of the rubber joints should be less than the support force of the pipeline, so as to prevent pulling off under pressure during work.

(4) the pipeline must have a fixed support or a fixed bracket, and the force of the fixed bracket must be greater than the axial force. In vertical installation and overhead installation, corresponding fixed supports and force supports should be installed at both ends of rubber joints to prevent pulling off after working under pressure.

(5) when installing the rubber connector, the bolt screw should be extended to the outside of the connector, and the mounting bolt should be tightened symmetrically and gradually to prevent partial leakage.

(6) flanges for rubber joints shall be valve flanges or flanges conforming to GB/T9115.1 (RF).

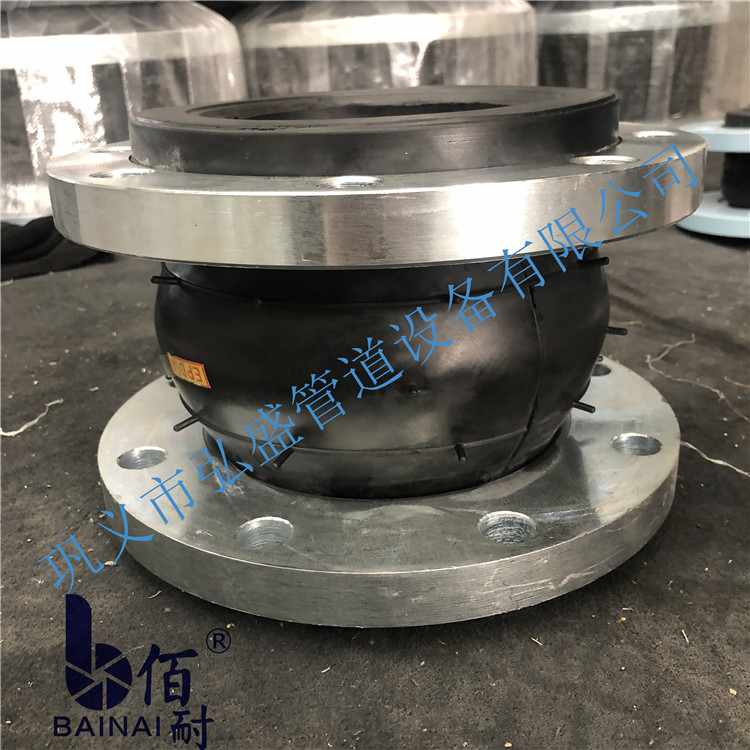

Double ball rubber joint

Principles: (1) selection of flange must comply with the design requirements, design requirements, the maximum working pressure should be installed, and the highest working temperature, the working medium, flange material numeral factors such as comprehensive chooses appropriate forms and specifications of the flange, when selecting the connected to the equipment or valve flange, should according to not under the principle of equipment or a nominal pressure valve selection.

(2) due to different export standards and standards of equipment, the selection of equipment flange should match the equipment. Before selecting flanges, it is necessary to verify the selected standards of equipment and valves: DIN (European standard), ANSI (American standard), GB (national standard).

(3) bolts. Single head bolts should be used; And bolts of the screw should be extended to the outside of the joint, to avoid screw damage to the rubber joint; Bolt exposed wire buckle length should not 2~3 buckle is appropriate; The upper and lower bolt holes should be flush.

Other rectification measures

Since the refrigerating machine room has been basically formed, and the delivery is imminent, it can only be partially rectified. Other rectification measures are as follows :(1) change the flange and rubber soft joint to match the sealing surface. (2) both ends of the vertically installed rubber joint shall be installed with anti-loosening anti-pull bolts to prevent pulling after working under pressure. (3) rectify the flanges whose parallelism and spacing do not meet the requirements according to the specifications; (5) follow-up rectification measures, such as replacing rubber soft joints with metal joints, reduce the risk of leakage and so on.